The alkaline etching fluid recycling copper extraction system is used to treat and recycle the alkaline etching solution used in the copper etching process. It extracts and recycles the copper ions in the solution by recycling it, thereby reducing the need for waste liquid treatment, reducing costs, and improving resource utilization efficiency. The system usually includes liquid circulation, copper recovery and regeneration treatment, and the final liquid cleaning and filtration steps.

Alkaline Etching Fluid Recycling Copper Extraction System

The alkaline etching fluid recycling copper extraction system comprising a main control unit, a collection unit, a blending unit, an electrolysis unit and a recycling unit, wherein the collection unit comprises a collection cylinder and an old liquid storage tank; the collection cylinder is connected to the wastewater outlet of an etching machine; the blending unit comprises a circulating pump and a circulating bath; the electrolysis unit comprises plural electrolytic baths; the recycling unit comprises a regenerated liquid storage tank, a regenerated liquid regulating tank and a regenerated sub liquid storage tank; the inlet of the circulating bath is communicated with the outlet of the old liquid storage tank; the outlet of the circulating bath is communicated with the inlet of each electrolytic bath; the outlet of each electrolytic bath is communicated with the inlet of the regenerated liquid storage tank; the inlet of the regenerated liquid regulating tank is communicated with the outlet of the regenerated liquid storage tank; the outlet of the regenerated liquid regulating tank is communicated with the inlet of the regenerated sub liquid storage tank; the outlet of the regenerated sub liquid storage tank is communicated with the etching machine.

Alkaline Etching Fluid Recycling Copper Extraction System

Alkaline Etching Fluid Recycling Copper Extraction System Process

The process of recovering copper from alkaline etching fluid mainly includes the extraction electrolysis process and direct electrolysis process.

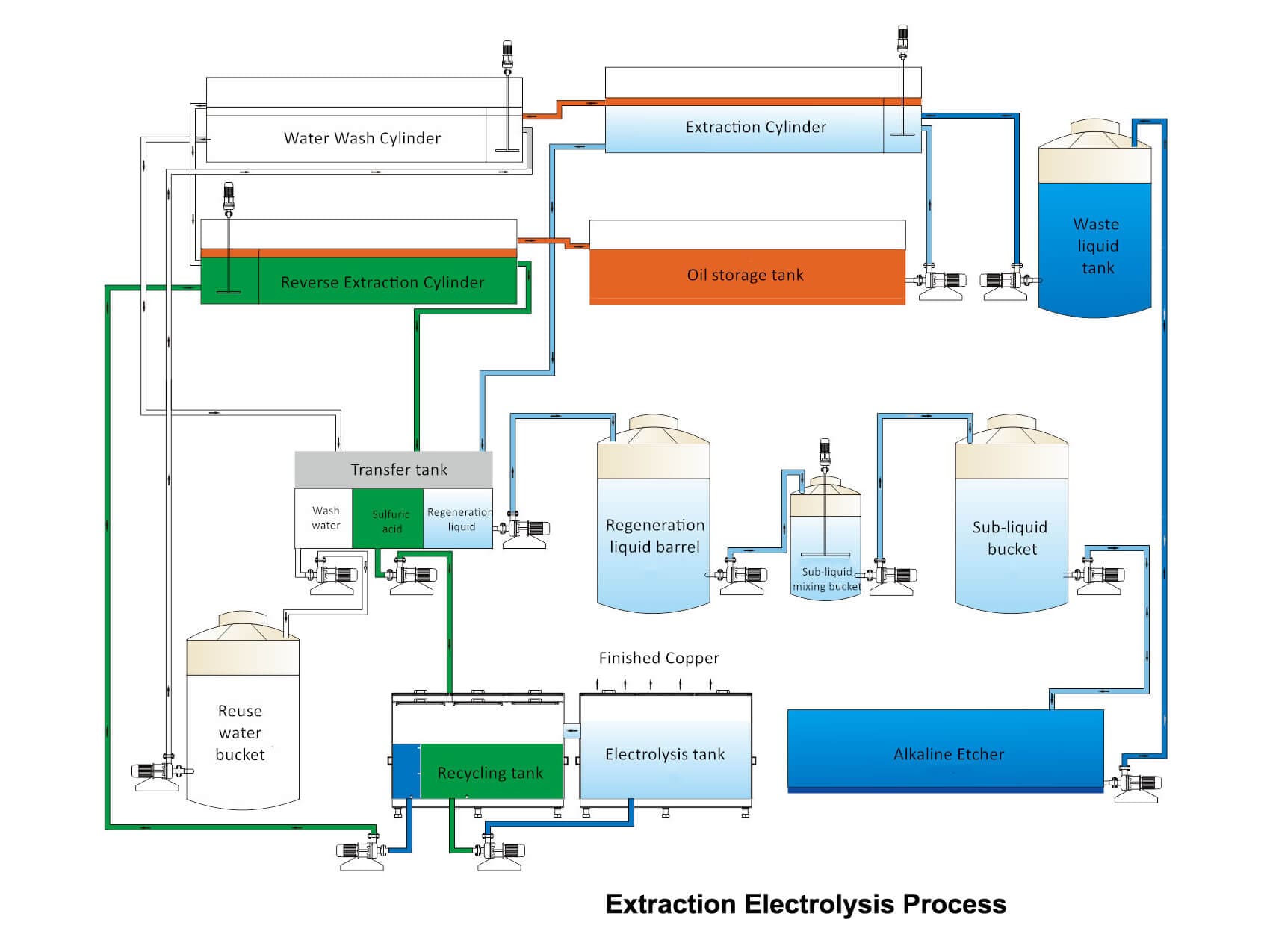

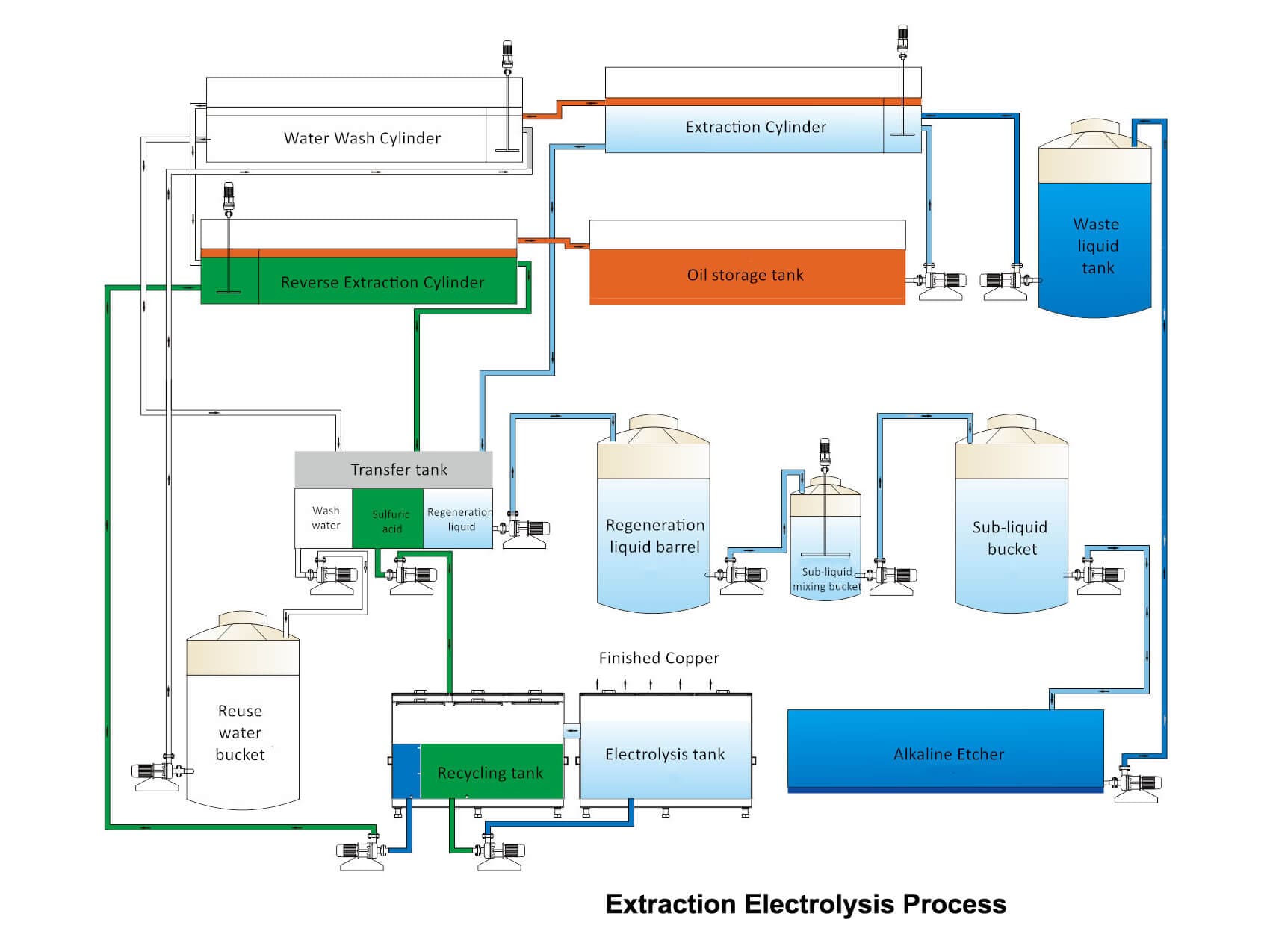

Extraction Electrolysis Process

The extraction electrolysis process in an alkaline etchant recycling copper extraction system is a critical step for extracting and recovering copper from the etchant. This process is highly efficient and environmentally friendly, and by recycling and recovering copper, it reduces the need for fresh resources and lowers the cost of waste solution disposal.

Working Principle and Process

The alkaline etching fluid recycling copper extraction system adopts the process of extraction separation – electrodeposition of copper. Extraction separation is to separate the copper ions in the waste etching solution so that the waste etching solution can be regenerated. After adjusting the parameters, the regenerated etching solution can be returned to the etching machine for recycling. The electrodeposition of copper is the electrodeposition of extracted copper ions into high-purity electrolytic copper.

Features

The waste etching solution is regenerated, and the regenerated etching solution can be recycled.

The copper ions in the waste etching solution and ammonia washing water were recovered to reduce to high-purity copper with a high copper recovery rate.

The equipment is simple to operate and maintain and does not affect production during installation and debugging. After installation and debugging, it can be put into use.

Alkaline Etching Fluid Recycling Copper Extraction System – Extraction Electrolysis Process Technical Parameters

| Model | Waste Liquid Treatment Capacity (Tons/Month) | Electricity Load (kW) | Copper Production Capacity (Tons/Month) | Occupied Area(m2) |

| YZ-JXCQ-30 | 10-30 | 30 | 3 | 60 |

| YZ-JXCQ-50 | 50-100 | 60 | 5 | 100 |

| YZ-JXCQ-100 | 100 | 90 | 10 | 200 |

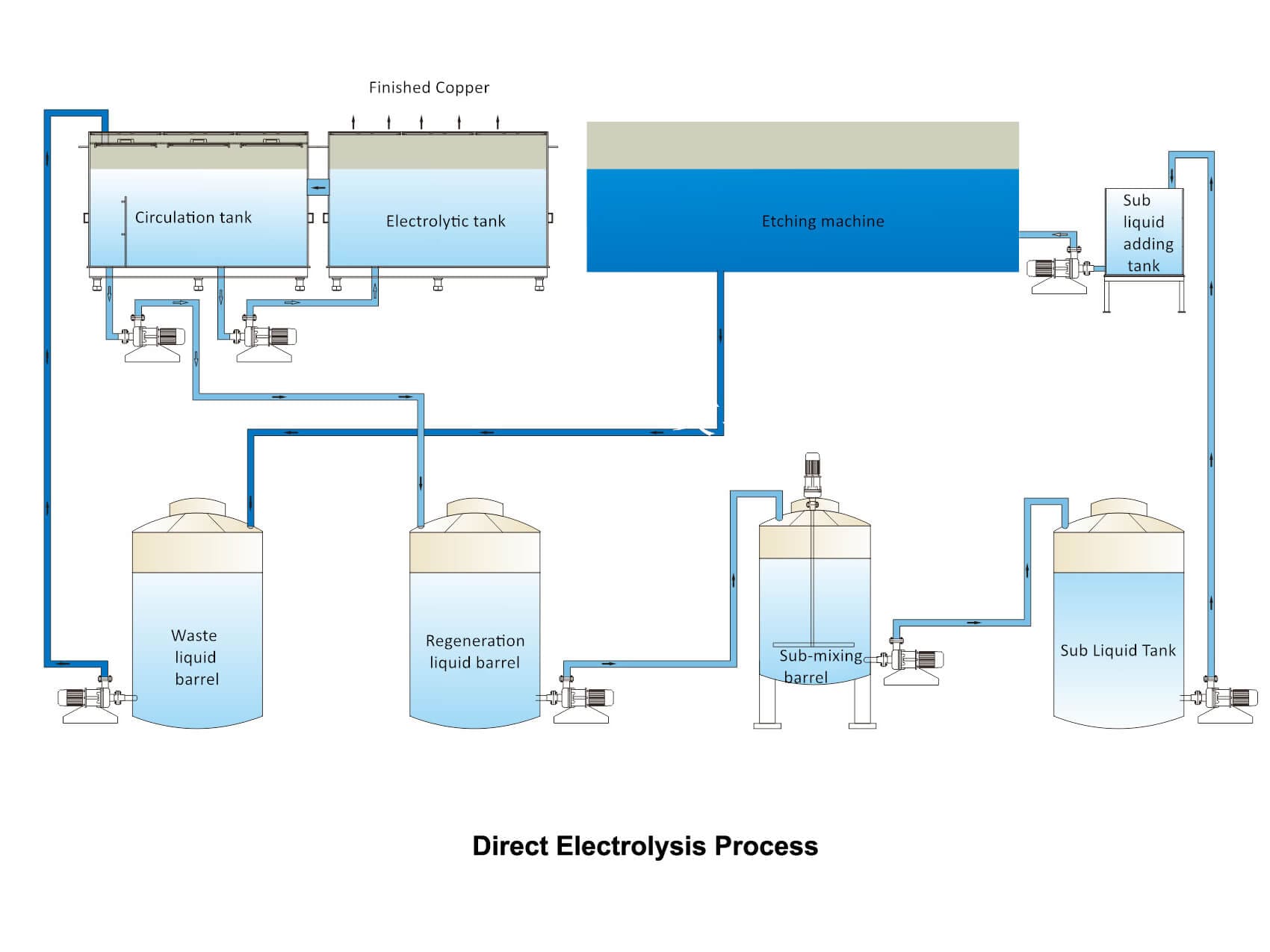

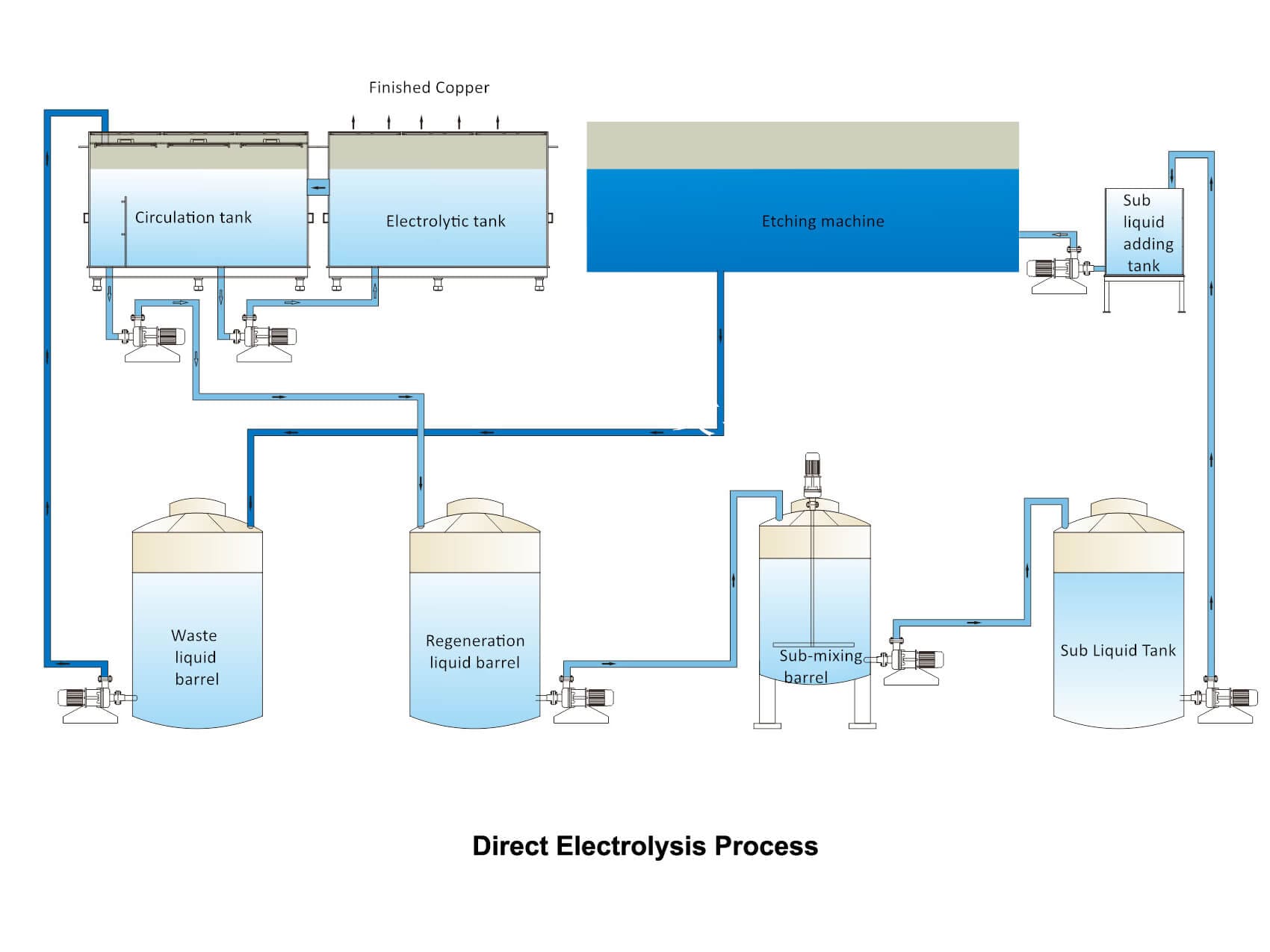

Direct Electrolysis Process

The alkaline etching fluid recycling copper extraction system through a direct electrolysis technology, not only can recover metal copper ions in etching wastewater but also can recycle etching solution, so as to realize zero-pollution online circulation; the alkaline etching solution copper recycling and regenerating system can meet safety index and environmental protection requirements.

Working Principle and Process

The direct electrolysis process of alkaline etching fluid recycling copper extraction system is to use special materials composite anode and cathode for direct electrolysis of alkaline etching solution with high copper content. High-purity elemental copper is deposited on the cathode plate. The solution after copper removal maintains the original chemical composition of the etching solution. After effective processing and allocation, the regenerated liquid with stable engraving ability can be automatically controlled by the specific gravity signal to add back the etching line for etching work, to realize the recycling of resources.

Alkaline Etching Fluid Recycling Copper Extraction System Process

Features

The composition parameters of the regenerated liquid are stable, and the etching rate and etching factor after reuse are similar to that of the purchased liquid phase.

The electrolytic workshop is equipped with an independent liquid ammonia storage room and an ammonia detection alarm, which is controlled by a linkage PLC. If there is any ammonia leakage, the power supply of the water spraying device will be turned on immediately and the standby fan will be turned on at the same time.

The exhaust gas tower is set to automatically add a control device, calibration, and maintenance of the induction probe at regular intervals, to prevent the exhaust gas discharge from being up to standard;

Storage containers are set with double high-level induction alarms to prevent solution leakage;

Regenerated liquid can achieve 100% reuse;

Equipment covers a small area, with a low cost.

Alkaline Etching Fluid Recycling Copper Extraction System – Direct Electrolysis Process Technical Parameters

| Model | Waste Liquid Treatment Capacity (Tons/Month) | Electricity Load (kW) | Copper Production Capacity (Tons/Month) | Occupied Area(m2) |

| YZ-JXDJ-30 | 10-30 | 30 | 3 | 30 |

| YZ-JXDJ-50 | 50-100 | 60 | 5 | 40 |

| YZ-JXDJ-100 | 100 | 90 | 10 | 50 |