Setting Up a Scrap PV Solar Panel Modules Processing Facility: A Path to Profit

As the use of solar energy continues to grow, so does the need to manage the waste generated by old and damaged solar panels. Setting up a facility to process scrap PV (photovoltaic) solar panel modules can be a profitable business venture. Here's how you can get started and make money in this emerging industry.

1. Understand the Market Potential

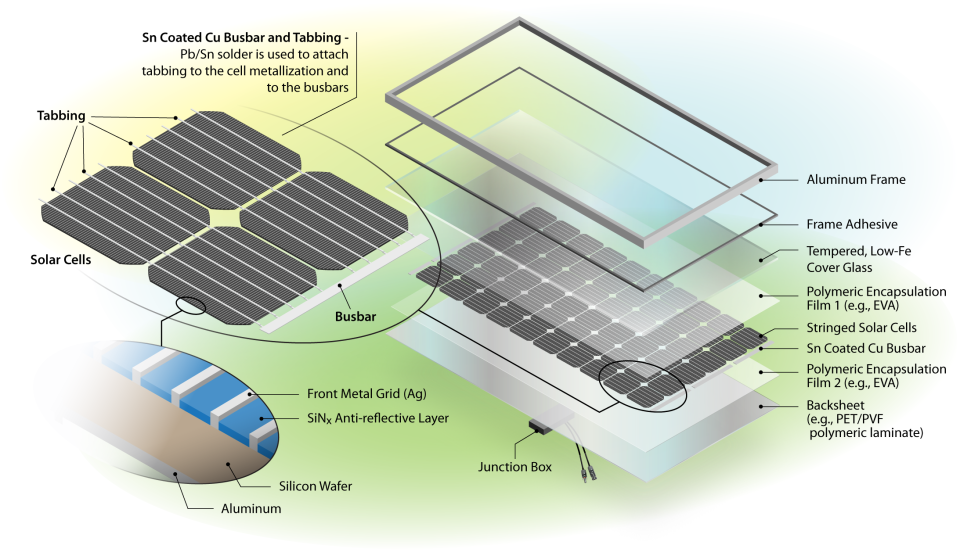

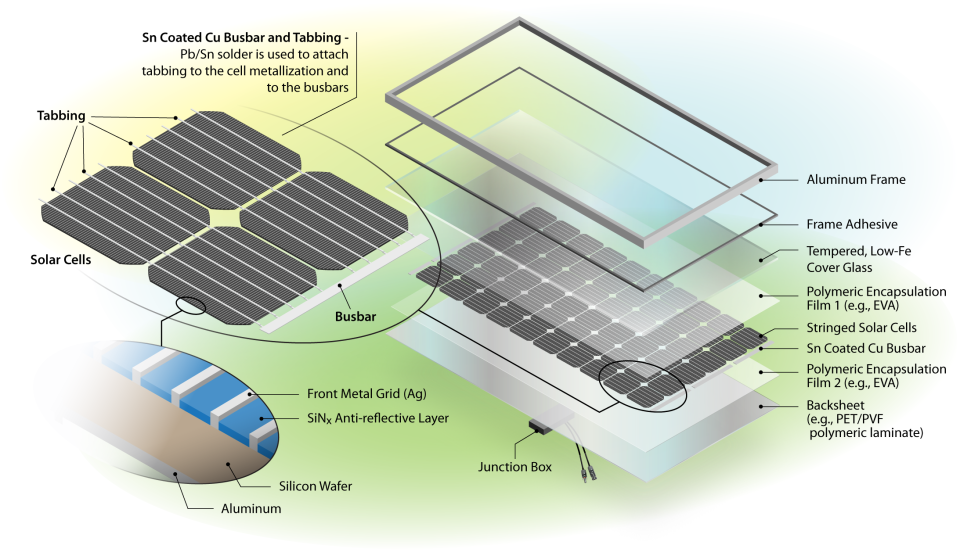

Solar panels have a lifespan of about 25-30 years, meaning that many of the early-installed panels are now reaching the end of their useful life. According to the International Renewable Energy Agency (IRENA), the world could see up to 78 million metric tons of solar panel waste by 2050. This creates a significant demand for recycling facilities. By processing these panels, you can recover valuable materials like aluminum, glass, silicon, and metals like copper and silver. These materials can be sold or reused, making the recycling process not just environmentally friendly but also financially rewarding.

2. Choose the Right Location

When setting up a processing facility, location is crucial. Choose a place close to sources of scrap solar panels, such as areas with many solar farms or residential solar installations. Proximity to transportation networks is also important to minimize logistics costs.

3. Invest in the Best Recycling Machines

To efficiently process scrap solar panels, you need reliable and efficient recycling machines. Modern recycling machines can separate and recover valuable materials with high precision, maximizing your profit potential.

Top Manufacturers to Consider:

· Italiana Rifiuti: Known for their advanced recycling technology, they offer machines that are both efficient and durable.

· MG Recycling: An Italian manufacturer specializing in equipment for recycling various types of waste, including solar panels.

· Jiangxi Mingxin: A leading Chinese manufacturer that offers state-of-the-art recycling machines specifically designed for solar panels. Mingxin’s machines are known for their high recovery rates and cost-effectiveness, making them a smart investment for any recycling facility.

4. Plan Your Facility Layout

Your facility should be designed to streamline the recycling process. Start with a designated area for incoming panels, followed by stations for removing frames, glass, and junction boxes. After that, the panels are shredded, ground, and sorted to recover valuable materials. Ensure your layout allows for efficient movement of materials from one stage to the next.

5. Compliance and Sustainability

It’s important to comply with local regulations regarding waste processing and recycling. Obtain the necessary permits and ensure your facility meets environmental standards. Operating a green and sustainable business not only benefits the environment but also enhances your brand’s reputation, attracting more customers.

6. Investment vs. Potential Income

Setting up a solar panel recycling facility involves an initial investment in machinery, typically ranging from $100,000 to $500,000, depending on capacity and technology. For example, a medium-sized facility processing 1,000 tons of solar panels annually might invest around $250,000 in equipment.

With the right setup and efficient machines, you can recover up to 95% of the materials from solar panels. Here’s a breakdown of potential income:

· Recovered Materials:

o Aluminum: $1,800 per ton

o Glass: $50 per ton

o Silicon: $1,000 per ton

o Copper and Silver (combined): $6,000 per ton

For a facility processing 1,000 tons of panels annually:

· Aluminum: 80 tons = $144,000

· Glass: 500 tons = $25,000

· Silicon: 200 tons = $200,000

· Copper and Silver: 50 tons = $300,000

Total Annual Revenue: $669,000

Additionally, by offering recycling services to solar companies, you can charge a fee per ton of panels processed, potentially adding another $100,000 to $200,000 annually.

Payback Period: With an investment of $250,000 and annual revenue of $669,000 to $869,000, you could recover your initial investment within the first year of operation, making this a highly profitable venture.

7. Start Marketing Your Services

Once your facility is up and running, start marketing your recycling services. Highlight the environmental benefits and the cost savings for companies that recycle with you. Offer competitive pricing and excellent customer service to attract and retain clients.

Conclusion

Setting up a scrap PV solar panel modules processing facility is a smart way to tap into a growing market. By investing in top-notch recycling machines from reputable manufacturers like Italiana Rifiuti, MG Recycling, and Jiangxi Mingxin, you can create a profitable business that also contributes to a cleaner planet. Start planning today, and turn waste into wealth!